Tel: +86-531-86196301

Email: sales@niutech.com

Email: sales@niutech.com

48/F, Greenland Puli Center, No. 25 Gongqingtuan Road, Shizhong District, Jinan, Shandong, China

loading

Niutech Pyrolysis

| Availability: | |

|---|---|

| Quantity: | |

Product Description

What is waste pyrolysis technology?

Plastic Pyrolysis is a chemical reaction. By thoroughly decomposition, the polymer in waste plastic can be cracking into small molecular or monomers, producing pyrolysis oil. After refining, the pyrolysis oil can be used as the raw material for the production of new plastics. Under the premise of safety, environmental protection, continuous and stable operation, the chemical recycling of waste plastics can be realized.

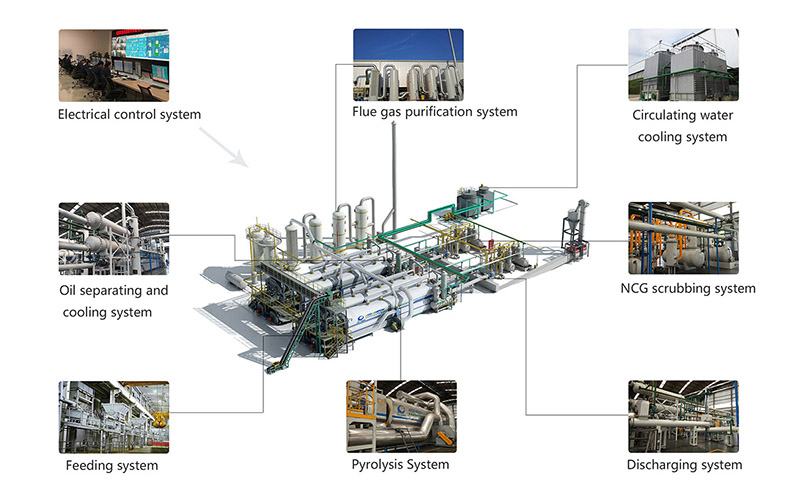

Sub Systems of Waste Plastic Pyrolysis Machine

Detailed information about the sub-systems of plastic waste recycling machine→

Technical Parameters

Item | Content |

Feeding Raw Materials | All kinds of waste plastics, such as PP/PE/PS, single or mixed plastics |

End Products | Pyro oil, solid fuel |

Processing Capacity | 10000T/Y, 20000T/Y, 30000T/Y... Can be customized according to the processing capacity |

| Annual Running Time | 8000 Hours |

Production Form | Continuous operation; Continuous feeding and discharging |

Heating Form | Adjustable, constant temperature |

Working Pressure | <100Pa(G) |

Pyrolysis Temperature | Constant temperature pyrolysis, adjustable temperature |

Automatic Level | Fully automatic intelligent control |

Equipment Life | No less than 10 years |

Pyrolysis rate | >99.5% |

Environmemtal protection | Comply with the most strict local emission requirements |

End products

End Products | Application |

Pyro Oil | → Raw oil for oil refinery plant → To be burnt as fuel oil directly |

Solid Fuel | → To be used as fuel |

Main Technical Features Of Waste Plastic Pyrolysis Plant

● Wide Adaptability of Raw Material

Plastic waste pyrolysis plant can process all kinds of waste plastics, such as PP/PE/PS, single or mixed plastics.

● High Pyrolysis Rate, High Oil Yield

The pyrolysis rate can up to 99.5%.

Pyro oil can be burnt as fuel oil directly. Raw oil can be used for oil reinery plant. The solid fuel is to be used as fuel.

● Intelligent and Continuous Operation

PLC/DCS smart control system

Rectify a deviation automatically and alarm automatically.

24 hours continuous stable running.

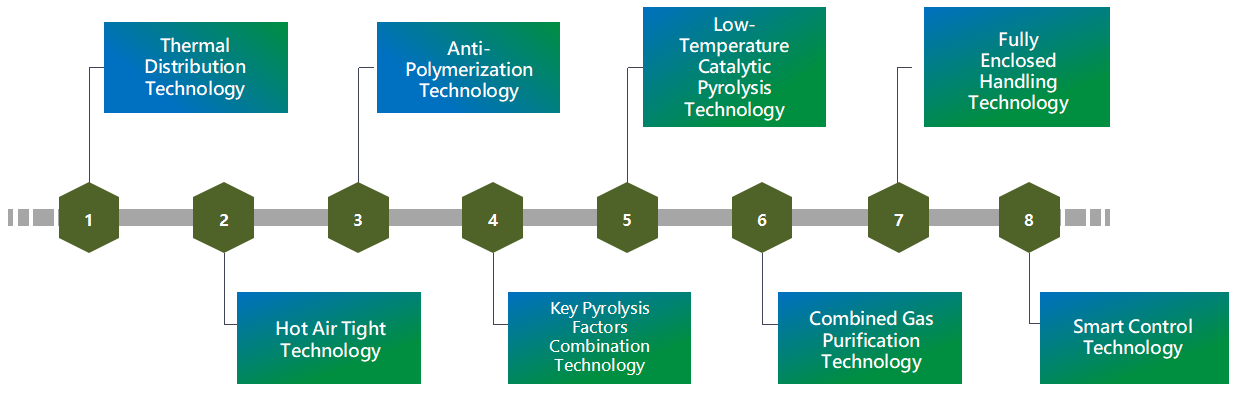

Core Technologies

Pyrolysis technology has some common difficulties, such as easy-coking of pyrolysis system, difficult dynamic sealing of feeding and discharging, and easy-polymerization of outputs.

The pyrolysis equipment designed and manufactured by Niutech contains nearly ten thousand technical parameters. Through the trial and error and systematic design for a series of key factors of pyrolysis technology such as heating temperature, heat transfer surface, operating pressure, and anti-polymerization techniques, Niutech have solved the technology difficulties above and realized continuous operation of pyrolysis equipment.

For detailed introduction, please click→

Video

Click for the video of waste plastic pyrolysis machine

Project Case

Project Case

Waste plastic pyrolysis production line has been running in Denmark, Thailand. The feedstock of Danish project is various and mixed waste plastic such as PP,PE,PS and so on. The pyro-outputs supplied to BASF to produce new plastics.