Tel: +86-531-86196301

Email: sales@niutech.com

Email: sales@niutech.com

48/F, Greenland Puli Center, No. 25 Gongqingtuan Road, Shizhong District, Jinan, Shandong, China

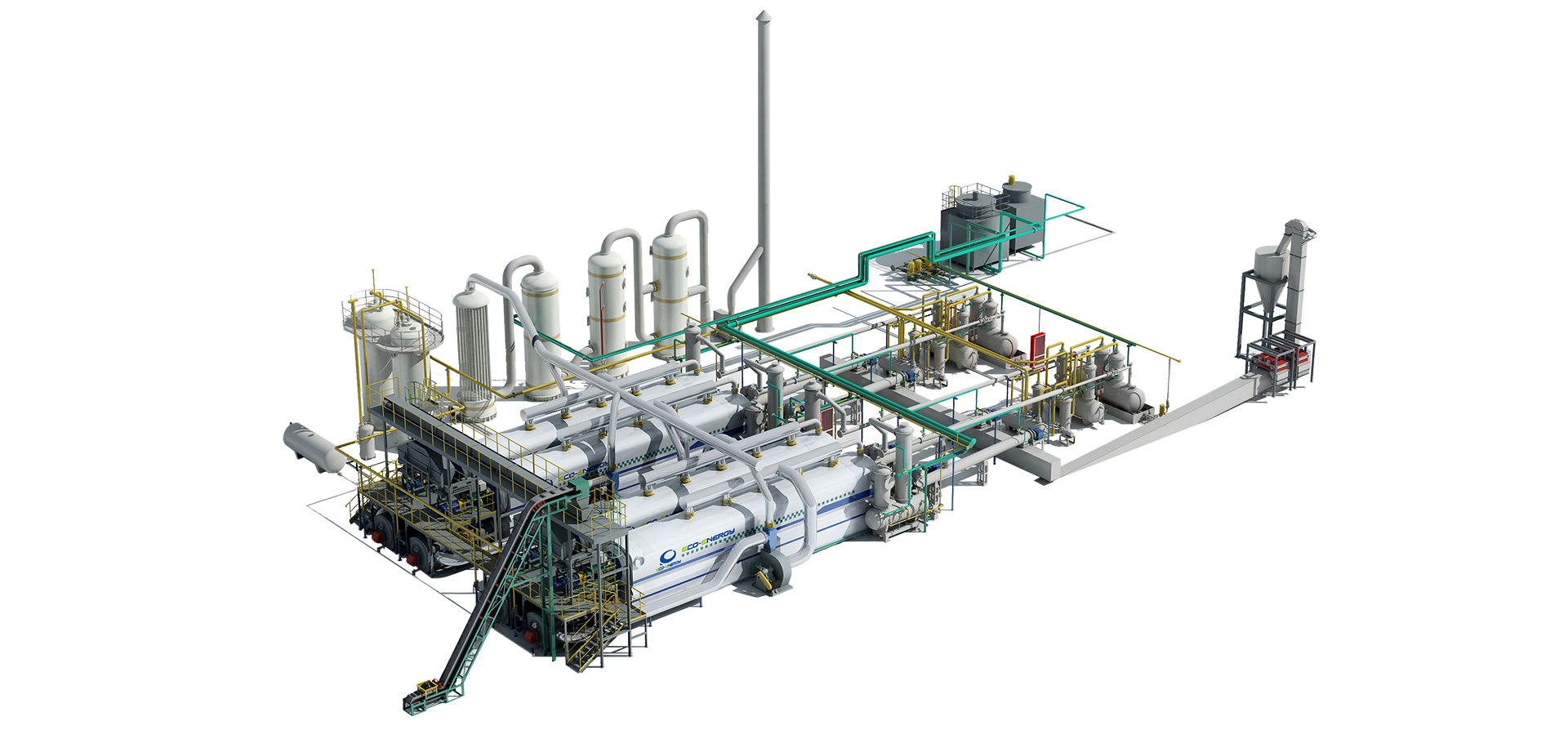

Pyrolysis system is the core system of all kinds of industrial continuous pyrolysis plant. In the oxygen-free or oxygen-poor environment , the pyrolysis system function is to complete the pyrolysis reaction of organic waste or hazardous waste and convert the raw material into fuel oil, NCG and solid output under normal pressure, low pyrolysis temperature or catalyst action.

Pyrolysis system is the core system of all kinds of industrial continuous pyrolysis plant. In the oxygen-free or oxygen-poor environment , the pyrolysis system function is to complete the pyrolysis reaction of organic waste or hazardous waste and convert the raw material into fuel oil, NCG and solid output under normal pressure, low pyrolysis temperature or catalyst action.  This system is to cool the gas phase output from pyrolysis reactor to a safe temperature and separate them according to the different boiling point. After cooling down, the condensed liquid oil with high boiling point will be temporary stored in the oil gathering tank and then be transported to the oil tank farm by liquid pump. The NCG with low boiling point will be transported into the NCG scrubbing system.

This system is to cool the gas phase output from pyrolysis reactor to a safe temperature and separate them according to the different boiling point. After cooling down, the condensed liquid oil with high boiling point will be temporary stored in the oil gathering tank and then be transported to the oil tank farm by liquid pump. The NCG with low boiling point will be transported into the NCG scrubbing system.  This main function is to cool down and purify the flue gas. Through multi-stage purification and comprehensive treatment, the harmful substances in the flue gas can be removed, the flue gas discharged into the atmosphere can meet the most strict national environment standards. This is a key factor to ensure the operation of the production line.

This main function is to cool down and purify the flue gas. Through multi-stage purification and comprehensive treatment, the harmful substances in the flue gas can be removed, the flue gas discharged into the atmosphere can meet the most strict national environment standards. This is a key factor to ensure the operation of the production line.