Tel: +86-531-86196301

Email: sales@niutech.com

Email: sales@niutech.com

48/F, Greenland Puli Center, No. 25 Gongqingtuan Road, Shizhong District, Jinan, Shandong, China

loading

| Availability: | |

|---|---|

| Quantity: | |

Product Description

What is pyrolysis technology?

Organics are unstable at high temperatures. Under the conditions of hypoxia and high temperature, macromolecules undergo the reaction of decomposition and condensation, converting into molecules of relatively small mass. Thereby, the water and organic matter in the oil sludge are separated from soil.

Under the premise of safety, environmental protection, continuous and stable operation, the hazardous waste pyrolysis production line can realize the resource, harmless, and reduction treatment of hazardous waste.

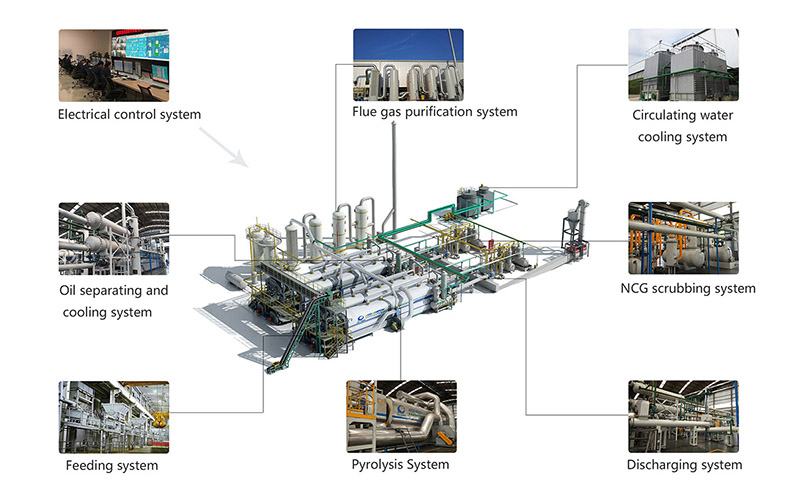

Sub Systems of Hazardous Waste Pyrolysis Machine

Detailed information about the sub-systems of hazardous waste recycling plant→

Technical Parameters

Item | Content |

Feeding Raw Materials | Hazardous waste, such as coal tar residue, waste mineral oil, waste resin, paint residue, chemical waste salt |

End Products | Depending on the raw materials, the harmless products are different |

Processing Capacity | 10000T/Y, 20000T/Y, 30000T/Y... Can be customized according to the processing capacity |

| Annual Running Time | 80000 Hours |

Production Form | Continuous operation; continuous feeding and discharging |

Heating Form | Adjustable, constant temperature |

Working Pressure | <100Pa |

Pyrolysis Temperature | Low-temperature catalytic pyrolysis, adjustable temperature |

Automatic Level | Fully automatic intelligent control |

Equipment Life | No less than 10 years |

Environmemtal | Comply with the most strict local emission requirement |

Technical Advantages

● High Eviromental Benefit

No chemical agents.

Whole pyrolysis process is completed in the closed pipelines to avoid the dust, VOC leakage issue and the secondary pollution.

● Low processing cost

No need sieving the stone.

Adopting the flue gas heat recovery technology for energy conservation and emission reduction.

Purified non-condenseble combustible gas could be used as fuel for supplying heat.

● High Automatic Control System

PLC/DCS automatic intelligent control system

Rectify a deviation automatically, alarm automatically

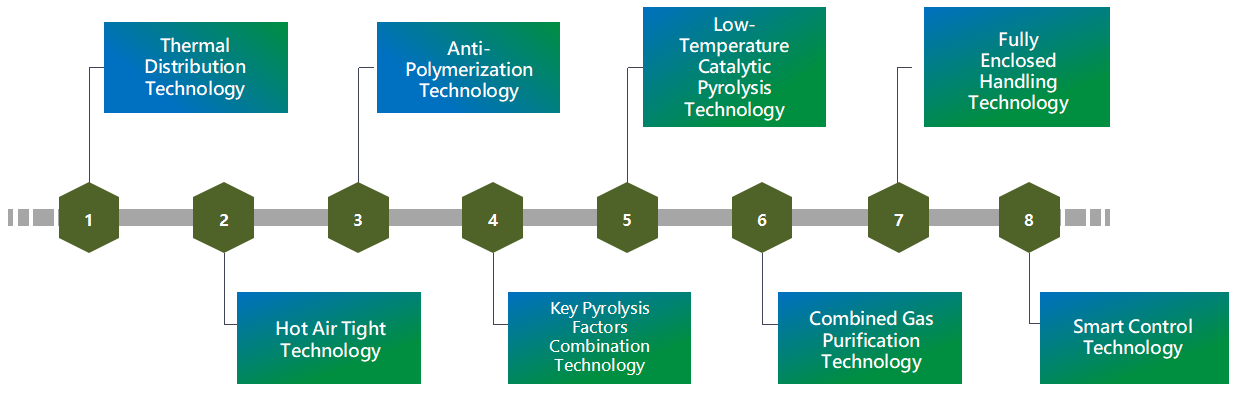

Core Technologies

Pyrolysis technology has some common difficulties, such as easy-coking of pyrolysis system, difficult dynamic sealing of feeding and discharging, and easy-polymerization of outputs.

The pyrolysis equipment designed and manufactured by Niutech contains nearly ten thousand technical parameters. Through the trial and error and systematic design for a series of key factors of pyrolysis technology such as heating temperature, heat transfer surface, operating pressure, and anti-polymerization techniques, Niutech have solved the technology difficulties above and realized continuous operation of pyrolysis equipment.

For detailed introduction, please click→